LX 1325 CNC Engraving Machine

Price 415000.00 INR/ Number

LX 1325 CNC Engraving Machine Specification

- Product Type

- CNC Engraving Machine

- General Use

- Wood, MDF, Acrylic, PVC Engraving and Cutting

- Material

- Cast Iron and Aluminum

- Type

- CNC Router

- Capacity

- 2000 x 3000 mm working area

- Weight (kg)

- Approx. 1200 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 3.5 kW

- Rigidity

- High

- Voltage

- AC 220V/380V, 50/60Hz

- Motor

- Stepper Motor

- Table Size

- 1300 mm x 2500 mm

- Spindle Speed

- 0-24000 rpm

- Axial Choice

- 3 Axis

- Dimension (L*W*H)

- 1700 mm x 2900 mm x 1700 mm

- Feature

- High Precision, Stable Performance, Durable

- Color

- Blue & White

- Spindle Power

- 3.2 kW Water-cooled Spindle

- Repeat Positioning Accuracy

- ±0.05 mm

- Cooling Mode

- Water Cooling

- Collet Type

- ER20

- Max Workpiece Height

- 200 mm

- Working Voltage

- 220V or 380V (Optional)

- Applicable Industry

- Woodworking, Sign Making, Advertising, Furniture Manufacturing, Mold Making

- Operating System

- DSP / Mach3 / NC Studio

- Command Code

- G code, HPGL, U00, mmg, PLT

- Max Travelling Speed

- 25000 mm/min

- Software Compatibility

- ArtCAM, Type3, Ucancam, JD Paint

- Drive System

- Rack & Pinion Transmission

About LX 1325 CNC Engraving Machine

Direction of Use & Application Method

To operate the LX 1325 CNC Engraving Machine, simply load your digital design using supported software and input the command code (G code, HPGL, U00, mmg, or PLT). The machine excels on surfaces such as wood, MDF, acrylic, and PVC. Secure the workpiece, then execute your project using the high-precision, water-cooled spindle. The semi-automatic system ensures repeatable, flawless engravings-ideal for woodworking, signage, and furniture applications. Regularly check spindle cooling to maintain first-class output.

Packaging, Supply Ability & Sample Exchange

Each LX 1325 CNC Engraving Machine is carefully packaged to withstand rigorous logistics and transit. The product's robust build and precise packing guarantee safety during delivery. Manufacturers and suppliers in India estimate a consistent supply ability to meet various order volumes. Sample units are available for potential buyers, allowing convenient exchange and practical evaluation before large-scale procurement. Our streamlined process ensures prompt dispatch and reliable after-sales support for your peace of mind.

FAQ's of LX 1325 CNC Engraving Machine:

Q: How can I operate the LX 1325 CNC Engraving Machine efficiently?

A: To operate the LX 1325, use the supported DSP, Mach3, or NC Studio operating systems, input your design file via compatible software, and ensure the workpiece is securely fixed. Routine checks on the water-cooling system are important for optimal performance.Q: What materials and surfaces can the LX 1325 engrave or cut?

A: The machine is designed for engraving and cutting wood, MDF, acrylic, and PVC, making it suitable for woodworking, advertising, furniture manufacturing, signage, and mold making.Q: When is a sample unit available for inspection?

A: Sample units of the LX 1325 CNC Engraving Machine are available upon request, allowing potential clients to evaluate performance and suitability before making a bulk purchase decision.Q: Where is the LX 1325 CNC Engraving Machine manufactured and supplied from?

A: The LX 1325 is manufactured and supplied by reliable manufacturers and suppliers based in India, ensuring quality production and prompt logistics services locally and internationally.Q: What is the process for estimating supply ability and organizing logistics?

A: The manufacturer provides an estimated supply ability based on your order specifications. Once confirmed, robust packaging and well-organized logistics ensure safe and timely delivery to your location.Q: How does the water-cooled spindle benefit machining operations?

A: The 3.2 kW water-cooled spindle maintains a stable operating temperature even during long production cycles, which ensures high precision, minimizes wear, and extends the machine's operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Router Machines Category

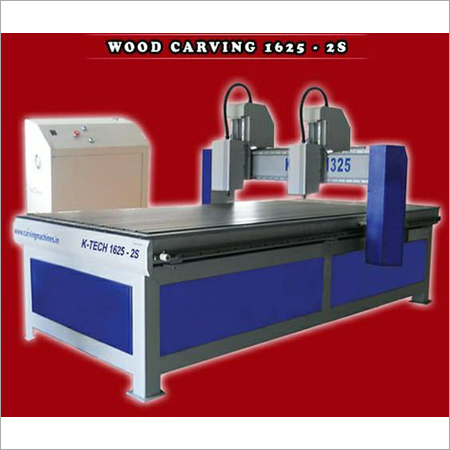

Double Spindle CNC Router

Price 490000 INR / Piece

Minimum Order Quantity : 1 Unit

Type : CNC Router

Voltage : 220V/380V (Optional)

Weight (kg) : Approx. 1350 kg

Dimension (L*W*H) : 3250mm x 2200mm x 1700mm

Single Spindle CNC Router

Price 395000.00 INR / Unit

Minimum Order Quantity : 1 Set

Type : Other, CNC Router Machine

Voltage : 220V/380V

Weight (kg) : 1200 kg

Dimension (L*W*H) : 1600 mm x 3100 mm x 1700 mm

Double Head CNC Wood Working Router

Price 490000.00 INR / Unit

Minimum Order Quantity : 1 Set

Type : Other, Industrial CNC Router

Voltage : 380V/50Hz

Weight (kg) : 1600 kg

Dimension (L*W*H) : 3200 mm x 2200 mm x 1700 mm

Double Head CNC Wood Router

Price 490000.00 INR / Number

Minimum Order Quantity : 1 Set

Type : CNC Router

Voltage : 220V/380V

Weight (kg) : 1200 kg

Dimension (L*W*H) : 3100 mm x 2200 mm x 1700 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS